Welcome to the future of FIBCs

Introducing

That’s “Packaging with a Purpose”

Packaging with a Purpose

FlexSack goes GREEN

Phase 1: Laying the Groundwork for a Greener FlexSack

Phase 2: Finding Sustainable Partners

Phase 3: Developing Sustainable Products

Phase 4: Planning for a Greener Future

In 2015, we made a commitment to be more sustainable in our production processes. That meant we needed to develop—and be able to supply—more sustainable solutions in the future.

The first step (which may have been so subtle that our customers didn’t even notice) was to ensure that our partners could provide bags that are constructed of a 100% polypropylene outer bag. We did this because not only does polypropylene thread produce a better product when used for sewing FIBCs, but also because this would make our bags more appealing to re-processors. At the time, most bag manufacturers used (and many still do) polyester threads to assemble their bags. In the recycling process, though, the polyester threads contaminate the polypropylene that re-processors use. That means that many re-processors won’t take bags made with polyester threads—making the ones crafted from 100% polypropylene more recyclable and sustainable in the long run.

Around the same time, FlexSack also changed our bale covers from the standard white fabric to green. We did this to keep us focused on our sustainability initiatives and in hopes that one day – both literally and figuratively- we will be known as the greenest bulk bag distributor in the U.S.

Make greenest bulk bag distributor in the U.S. font the brand standard green

Not only are we all about sustainability but we’ve also done the work to make sure that our production facilities are too.

When we decided to proceed with several sustainability initiatives in 2015, we communicated our goals to our overseas partners. We began implementing and developing new strategies to be more energy conscious, reduce waste, maximize efficiencies, and more. We also carefully vetted plants to confirm that they, too, were willing to make the shared commitment to sustainability.

So far, our hard work has paid off. Our key overseas partners have made significant strides in a variety of sustainability initiatives, such as:

SOLAR POWER: The solar panels on our overseas partners’ factories generate around 20 times less than the carbon output of coal-powered electricity sources.

SCRAP MANAGEMENT: In the past six months, we’ve decreased the total percentage of production waste from 8.43% to 6.94%. And we’re just getting started! We plan to reduce production waste by even greater numbers in the next few years.

RECYCLING: With proper load test reports, our overseas partners offer recycled FIBCs for non-food applications and have also invested in a new machine that will extract and reuse the high-quality polymers inside the bags.

A major part of our sustainability initiative is—you guessed it—creating sustainable products. That’s why we are excited to announce that FlexSack has developed—and is ready to introduce to the North American market—a brand-new line of bulk bags. These are aptly named FlexSack-eco.

A major part of our sustainability initiative is—you guessed it—creating sustainable products. That’s why we are excited to announce that FlexSack has developed—and is ready to introduce to the North American market—a brand-new line of bulk bags. These are aptly named FlexSack-eco.

The FlexSack-eco contains 20%-30% rPP, or recycled polypropylene. These bags will be woven will an equivalent percentage of green yarns throughout the body of the bags. The reason? The green threads will make these bags instantly recognizable to customers as FlexSack-eco. Plus, these threads are an excellent way to display how much PCR material we’ve saved from a landfill.

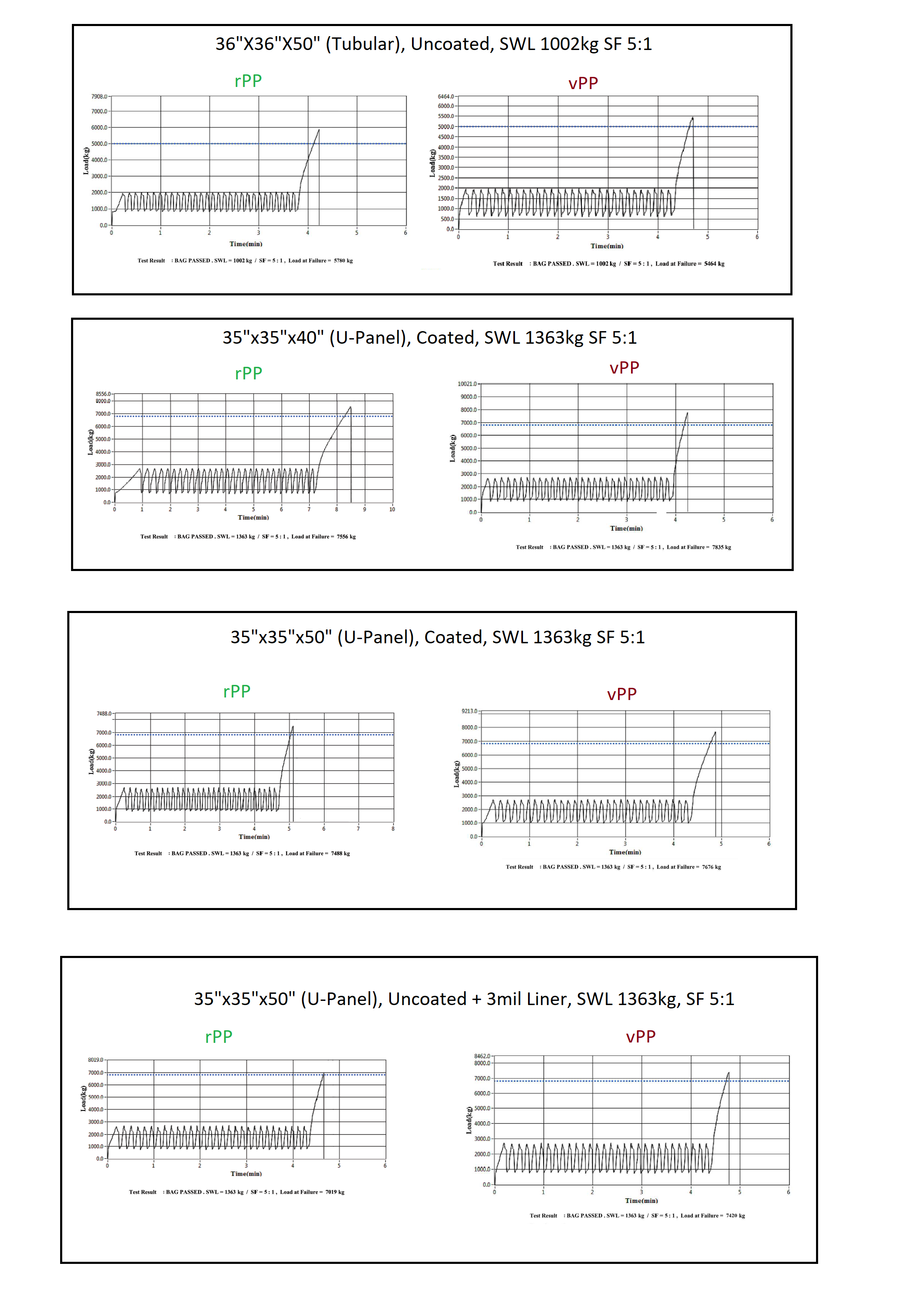

Customers can rest assured that our new FlexSack-eco bag will perform as well as any bag made of virgin materials, and we’ve got the test reports to prove it! The performance quality of the FlexSack-eco bags will not suffer as the bags meet equivalent test standards of a bag made with 100% virgin polypropylene—without the need for additional fabric weight. This is possible because the rPP retains its original strength.

Make all instances of FlexSack-eco the brand standard green

FlexSack is also developing a recycling program that will reduce the hundreds of thousands of FIBC bags that end up in landfills each year. We are committed to offering easy collection options and incentives to customers to encourage them to recycle our bags. This initiative has an added benefit, as our sustainability programs will help customers meet LEED credit qualifications.

By the end of 2024, our goal is to have a network of collection sites and re-processing partners as an end-of-life/post-use resource for our customers’ bags. If we reach this goal, we will succeed in significantly reducing the amount of polypropylene scrap and FIBCs in landfills each year.

Overall, we’ve got a lot of work to do and we know it won’t happen overnight. Whether you’re packaging dirt, pharmaceutical grade chemicals, or anything in between, we have the knowledge to design and deliver the packaging solution that best fits your needs. It’s our commitment to you—and to our planet—to be a sustainability leader in the FIBC industry.