Do you know the difference between our fibc fabrics?

Bulk Bags or FIBC fabrics are all about controlling static electricity, which is an imbalance of electric charges within or on the surface of a material. When bulk bags are rapidly filled and discharged, the flowing movement of finely powdered substances can cause a buildup of static electricity. Removing or preventing an electrical charge is critical in the packaging of flammable or combustible materials or in an environment where combustible dust may be present.

Type A FIBCs are made from plain woven polypropylene and other non-conductive fabrics. As there is no static protection provided by Type A FIBCs, it is essential that they are not used to store or transport combustible materials or used in flammable or combustible environments.

- Used to safely transport non-flammable products

- No flammable solvents or gases should be present around the bag.

Type B FIBCs are made from plain woven polypropylene fabrics that have a low breakdown voltage to prevent the occurrence of highly energetic propagating brush discharges that can ignite a dust-air mixture. Type B FIBCs cannot be considered antistatic because they do not have any mechanism for dissipating static electricity.

- Used to safely transport dry, flammable powders

- No flammable solvents or gases should be present around the bag.

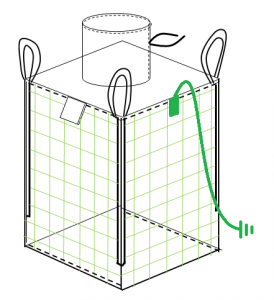

Type C FIBCs are made from non-conductive polypropylene fabrics interwoven with conducting threads, normally sewn in a grid pattern, that connect the bag to ground via a grounding point. The connection to ground or earth during filling and discharging is critical to the safe use of Type C FIBCs. As with any manual operation, ensuring interconnection and grounding of Type C FIBCs is subject to human error.

- Used to safely transport flammable powders.

- Used safely when flammable solvents or gases are present in the bag.

- DO NOT USE when ground connection is not present or has become damaged.

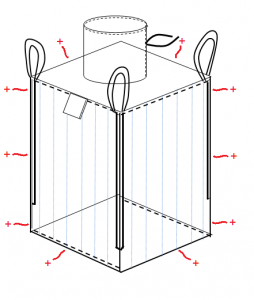

Type D FIBCs are made from antistatic and static dissipative fabrics designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges without the need for a connection from the bulk bag to the ground. Type D FIBCs can be used to safely package combustible products and to handle products in combustible and flammable environments.

- Used to safely transport flammable powders

- Used safely when flammable solvents or gases are present in the bag.

- DO NOT USE when the bag surface is contaminated or covered with conductive materials, such as water or grease.

When to Use Plain and Antistatic FIBCs

| Bulk Product: MIE (Minimum Ignition Energy) of Dust | Non-Flammable Atmosphere | Explosive Dust Atmosphere | Explosive Gas and Vapor Atmosphere |

| MIE > 1000 mJ (milli Joules) | A,B,C,D | B,C*,D | C*,D |

| 1000 mJ ≥ MIE > 3 mJ | B,C,D | B,C*,D | C*,D |

| MIE ≤ 3 mJ | C,D | C*,D | C*,D |

*Type C FIBCs are safe to use under these conditions ONLY IF PROPERLY GROUNDED.

Discuss your specific shipping and storage needs with a FlexSack Expert today by calling 205.620.9889 or by emailing sales@flexsack.com.

TALK WITH ONE OF OUR FLEXSACK EXPERTS

GIVE US A CALL AT 205-620-9889

Get in touch

Physical address

Helena Industrial Park

545 Elm Street

Helena, AL 35080

Mailing address

P.O. Box 580

Helena, AL 35080